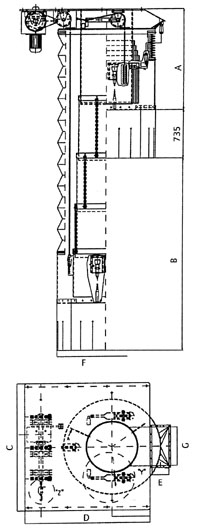

Gravel Loader Type Rondo DN 500, 600, 800

Areas of application

Areas of application

The gravel loader TYPE RONDO DN 500 - DN 800 are special loaders for the loading of coarse grained bulk materials, e.g. gravel stones, gravel stone chips onto open lorries or railway carriages. Models with extended lift are suitable for ships and stock pile loading.

The required exhaust air of approx. 2000 - 3000 m3/h/m dust cloud can be exhausted through the suction piece via a suitable de-dusting plant. Loading thus proceeds virtually dust-free. For loading capacity up to 300 m3/h in stone peeble and sand areas the RONDO TYPE 500 is well suited.

For use in the gravel- and hard-stone industry the types RONDO 600 and 800 with their special abrasion protection pipe inserts are ideally suited. The repeatedly revolvable and easily exchanged abrasion protection pipes of Hardox 400 significantly increase service life. Customer-specific wall thicknesses up to 20 mm and the use of special, abrasion protection steels lower the operating costs.

Compact loader models with integrated high-performance lifting capstan and the required limit switches facilitate economical installation possibilities. Due to the factory adjusted and installation friendly design, final installation can be effected by customer personnel. Direct attachment to conveyor belts or under loading stations is realized without problems.

Because of the varying discharging parameters of the various grain sizes an optimum bulk material entry into the loading equipment is not possible. Abrasive wear can be pre-determined according to the type of bulk material. Because of the good construction of the equipment the special inlet pipe can be maintained economically by your own operating personnel by revolving in many times and by exchanging the worn areas.

Operation

The compact design permits an economical expansion possibility. Depending on varying conditions, wear zones in the inlet pipe are minimized to customer specifications. The loading unit installed under the conveyor belt or over the discharge point permits bulk material loading ranging from coarse through fine grained down to dustypowdered materials. High loading performances are accomplished economically.

Optimally designed exhaust pipe connections make good exhaust performances possible which allow a practically dust-free loading operation.

The discharge cone and the inner pipes of the loader are lowered onto the vehicle with electrical controls and suspended push buttons. The content indicator of the cable tension switch signalize contact with the flat bed lorry body or the maximum extended condition. The lifting capstan is stopped in its downward movement.

The rising bulk material activates the level indicator during loading and the discharge cone is raised.

Raising speed is to be selected so that the dust skirt will not lift itself off the bulk material. Raising by approx.

200 mm when reaching the level indicator, dwelling time of approx. 4 sec in the raised position reduces dust development even during vehicle movement und permits automatic laoding.

CAUTION: A weight limitation during loading via a scale or a timer control is to be scheduled.

Design

Design

Exterior parts are sand blasted, primed and hammertone silver-grey finished or painted with high quality coatings.

Inside pipes: normal steel, Hardox or special steels.

Dust dome of conveyor belt: rubber

Wear protection pipe with wall thicknesses up to 20 mm are available.

Technical data

Standard width: DN 500 - 800 mm

Loading capacity: 300 bis 800 m3/h

Building height: 1600 mm + dust skirt: 735 mm

Telescoping length: 3000 mm

Suction capacity: 6.000 - 12.000 m3/h

Power supply: 400, 500 oder 690 V AC

alternative: inside pipes of Hardox-400 or special wear-protection steels.

Advantages

· Compact construction

· Economical installation possibility

· Ready for connection, all inside components pre-wired

· Variable design with or without wear protection pipe

· Gravel loader can also be built into transport frame

| DN | A Bui. Height |

Dusk Skirt |

B Lift |

C | D | E | F | G |

|---|---|---|---|---|---|---|---|---|

| 500 | 1600 | 735 | 3000 | 1260 | 1485 | 200 | 1000 | 600 |

| 600 | 1600 | 735 | 3000 | 1800 | 1735 | 300 | 1350 | 600 |

| 800 | 1600 | 735 | 3000 | 2000 | 1935 | 300 | 1500 | 600 |