Blow Down Valves

Blow Down Valves

At the bottom of the steam boiler, sludge settles, which is discharged through the sludge device.

Steam boilers must be blown down to remove concentrations of solids which would otherwise build up in the boiler water. Excessive dissolved or suspended solids would cause the boiler water to foam which would result in unstable water levels and may allow scale to form on the boiler tubes.

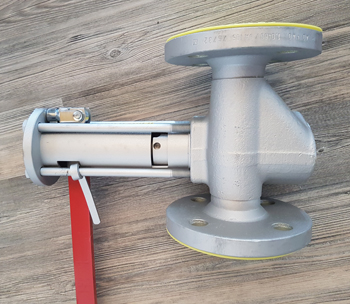

The blow down valve intermittent blowdown valve is set to the open position using a lever. Here, the pressure pin forces the spring-loaded valve plug out of the valve seat, opening up a large cross section. The resulting suction removes settled sediment on the floor of the boiler, also known as boiler sludge, from the boiler.

The blowdown action is only effective for the first two seconds. Longer opening times lead to water losses.

Blow down valves could deliver with manual or pneumatic actuator.