Compressors

Application fields and use:

The units are specifically designed to match practical requirements in the field. They are the ideal solution for the dry, oil-free and clean compression of air and neutral gases as requires e.g. in the following application fields:

- pneumatic conveying with air or nitrogen

- aeration of sewage basins

- homogenising of cement

- vacuum production in the glass industry

- prevention of ice build-up in harbours and lakes

- oil booms

- gas-air mixing plants

- oxidation air for power stations

- stationary unloading of silo vehicles

- vacuum production in the paper industry

- conveying and compressing of neutral gases

- blast air for production of spunbonded web

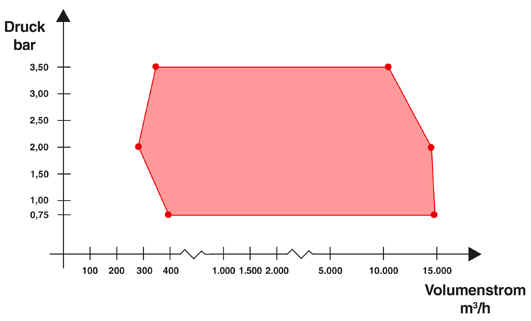

The compressors are manufactured as air-cooled units for intake volumes from 200 bis 15.000m³/h hergestellt.

Discharge pressures of up to p2 = 3.0 bar and 4.5 bar (abs.) dry, oil-free compression, temperature limit t2 maximum 250° C.

Vacuum operation is possible with the standard VML-compressors to a maximum of 70 % (0.3 bar abs.) and as a modified unit to 85 % (0.15 bar abs.).

RANGES OF PRESSURE

In overpressure two discharge pressure ranges are available.

VML up tp 3.0 bar (a) - VM up to 4.5 bar (a)

in vacuum pressure:

VML up to 0.3 bar (a) - up to 0.15 bar (a) with pre-inlet

SIMPLE OPERATION

All operation and maintenance elements are accessible from one side, this includes instrument panel, oil filter, oil level sight glasses, air- and oil filters and therefore enable a simple operation and maintenance.

LARGE OR SMALL PERFORMANCES

With all the units of the series, rotor profile, internal compression ratio and accessories can be optimized to meet individual requirements.

TECHNOLOGY

The units are delivered complete with internal installation, pipng and wiring, and are ready for connection to the customer's system. By using a frequency converter the volume can be regulated over a large range with a ratio of approximately 1:4. Relatively small rotor diameters and low risk of internal contamination preclude any additional imbalances that could increase vibration. Even under difficult operating conditions the calculated bearing lifteime is more than 40.000 hours.

ADAPTABILITY

Depending on customer requirements the scope of supply can include for example:

- driving motor

- control- and power cabinet

- acoustic hood

- start-up unloading device

- full load / idle running system

DRIVING SHAFT

sealed by peak seals, working maintenance-free in combination with a well-aimed oil-chamber release..

CHASSIS

The base frame for the compressor stages with belt drive has several functions. It is base support for the compressor stage, suction-silencer and oil reservoir in one. That reduces costly installation surface.

WITH BELT DRIVE

The belt drive of the units is designed so that v-belt tension is constant in all operating conditions. The weight of the motor mounted on a hinged support ensures that the tension of the v-belts is always as it should be.

ENERGY CONSUMPTION

Depending on the maximum discharge pressure 3 + 4 or 4 + 6 screw profiles are used. This results in an optimum use of energy despite other influences such as tolerances, pressure losses at accessories and deflections of the volume flow.

EFFICIENCY

During the whole operation period of the compressor the efficiency remains virtually constant so that no reduction of the conveying capacity will occur.

SCOPE OF SUPPLY AND PERFORMANCES

Belt drive

|

Gearbox

|

Items also belonging to the basic unit:

|