Blower Units

Fields of application:

The blower unit has been designed for the conveying of clean air.

The flexible modular design makes it possible to combine the accessories of one nominal flange size with corresponding blowers and motor sizes. With all the possible motor sizes and corresponding V-belt drives that can be fitted to one basic frame it is possible to match the present requirements very closely but still leave scope for future operating changes.

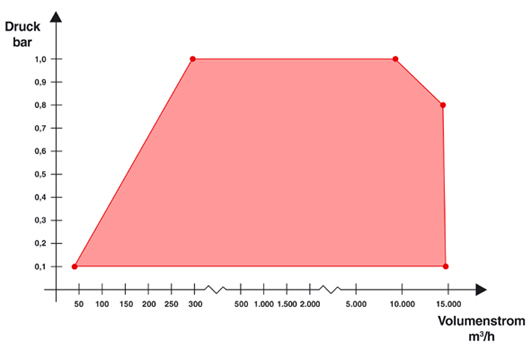

The blowers are available in 16 sizes for intake volumes from 30 m3/h up to 15.000 m3/h and discharge pressures up to 1000 mbar depending on the blower size. Higher intake volume flows on request.

Fields of application for standard design:

Water Treatment:

- Basin aeration

- Filter flushing

Pneumatics:

- Pneumatic conveying of bulk materials for example foodstuffs, granulated plastic material, cement and many other materials.

Other areas of the process industry and environmental protection.

Construction and manufacture:

Blower

The blower has three-lobe rotors and the cylinder housing has pre-inlet channels to reduce sound emissions through pulsation cancellation. The cylinder, end plates and covers are made from EN-GJL-200.

Rotors

The lobe-rotors, sizes GM 3 S to GM 80 L are one-piece-drop-forged steel of C 45 N.

GM 90 S to GM 240 S the rotors are of GGG 40, the shafts are of C 45 N.

Cooling

Concevtion cooling via the housing surface is adequate for blowers operating within their thermal range as shown in the performance tables.

Lubrication

Bearings and timing gears are splash lubricated.

Oilfree conveying (sealing)

The conveying chamber (cylinder) is sealed from the gear case and the front cover by piston ring labyrinth seals. These seals have a central, neutral chamber which is open to the atmosphere.

Timing gears

The helical timing gears are hardened and ground. They are fitted to the shafts by the oil expanded taper method.

The blower unit

By using a three-lobe blower in combination with the pr-inlet a pulsation decrease can be obtained and a completely new concept in package design is possible.

The ancillary items used to make up the complete unit are all mounted on the discharge silencer/Base assembly.

The assembly contains no absorption material and is wear-resistant, it has been designed tp produce constant noise reduction over the total speed range of the blower fitted to it. Additional silencers are not required under normal use.

Experience over many years with the use of V-belt drives has led us to develop them further.

The drive motor is mounted on a hinged motor support, this configuration means that the belt drive is always at its optimum tension and is retained automatically by the weight of the motor.

Each unit is delivered with all the standard items neede to operate the unit. Anti-vibration mountings are supplied as a standard, therefore, no special foundations are required.

Prompt ability of application

Connect conveying pipings, fill up lube oil, effect electrical connection and the blower is raedy for operation.

The mounting costs are kept to a minimum with this installation.