Air Conveyor Trough

for the horizontal transportation of dusty material

Application

The air conveyor trough is used for horizontal transportation of dusty material. (Semonimal) gravally products cannot be transported. Depending on the material type and conveying capacity, the air conveyor trough nust be installed with an angle of inclination betwenn 5° - 7°.

Material

Body: St 1203, AIMg 3 oder Mat. 4541 und 4571

Aeration plate: Synthetic substances or Sinter metall (Pewter bronze or VA)

Sealing: Rubber

Construction

The air conveyor trough consits of an upper- and lower box, which is separated by the porous aeration plate.

The dispersion air is blown into the lower box, while the material to be conveyed is being moved.

Both boxes are firmly screwed together and sealed against each other. The conveyor troughs are manufactured in pieces not longer than 2500 mm max. and can be screwed together to any length.

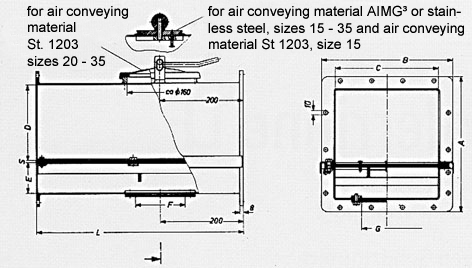

Appropriate in- and output elements are supplied. An air ventilator is normally used as air source, which is firmly mounted onto the conveyor trough. Ech conveyor trough section has a hand inspection part as shown in schematic.

Electrical equipment

As operating drive for the ventilator a special motor is used. Protection and voltage according to request.

Operation data:

Air volume/m2: dependent on trough inclination and porous material

Air pressure: dependent on porous material

Special features

Using the air conveyor trough, a gentle conveying of powdery material is guaranteed. Only limited obsolescence occurs as against mechanical conveying belts like screw conveyors as rotating parts are not used.

The aeration plate has a long lifetime and can often be regenerated. The hand inspection part allows a controlled operation and maintenance e.g. to clean the trough without dismanting.

Unlimited input- and output end elements can be installed. Conveying length does not matter, as long as enough height is available.

Measurement table

Construction ist subject to change.

Dimension Drawing