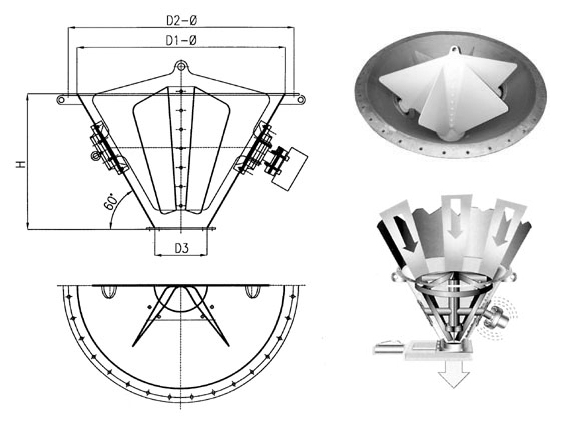

Discharge Hopper Vibrating Cage Type ASK

For the problem-free discharge of poorly flowing bulk goods from silos or bunkers

| D1-Ø | D2-Ø | Number of holes x Ø | cone height H, D3-Ø | kW |

|---|---|---|---|---|

| 1200 | 1300 | 32 x Ø 18 | as requested by the customer | 0,3 |

| 1500 | 1600 | 36 x Ø 18 | as requested by the customer | 0,3 |

| 1800 | 1900 | 40 x Ø 18 | as requested by the customer | 0,3 |

Areas of application

Areas of application

The discharge hopper vibrating cage, Type ASK serves as discharge aid for all poorly flowing and bridge-forming, dry, dusty, to granular, bulk materials.

Major advantage over air operated systems is that the discharged bulk materials do not contain fluidizing air. This has positive effects during bagging as well as when loading special bulk materials into silo vehicles. The flanged version with 60° outlet slope is easily attached to any silo or bunker - even retrofitted.

Operation

The vibration motor is switched on in a pulsating mode after opening the closure device, e.g. rotary valve or screw conveyor.

The optimally designed vibrating elements and position of the vibrating motor facilitates a direct application of the vibrating energy.

Through this pulsating oscillation the negative flow behavior is positively modified so that the material discharges. By changing the pulsating frequency, the centrifugal force as well as the revolvable positioning of the vibrator motor, the flowing behavior of the bulk material can be influenced decisively.

Material/design

Depending on the area of application, the ASK can be furnished in steel, as well as with motors with various centrifugal forces and voltage ratings.

Paintings: Hammertone silver grey.

Special lacquer, as well as various stainless steel qualities can be specified.

Advantages

- Absence of disturbing fluidizing air

- Simple installation and maintenance

- Compact design - no protruding components

- Wear resistant construction

- No vulnerable collars

- On request: Pressure and shock proofed up to 3 bar or pressure proof up to 7 bar and explosion proof

- Operational temperature up to 80° C

- Cone can be heated and insulated