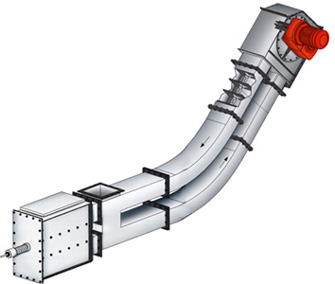

Cubic Chain Conveyor

Advantages:

Advantages:

- High conveying capacity more than 230 m3/h

- Versatile design

- Low energy consumption

- Absolutely dust-tight

- Low space requirements

- Low maintenance costs

- Low noise transport

- Minimal product degradation to granular materials

- Conveying distance up to 50 m horizontal or 30 m vertical

- Modular construction i.e. parts are common to many

different configurations - reduces spares inventory

- Minimal product retention in the conveyor, fast changeover

of product is possible

- Long running time due to low chain speed and a light conveying chain - reduces maintenance costs

- Conveying chain fixed in the center of the driving plate

Chain DIN 762 Ø 20 x 100: MnSi 5, surface hardened to 1 - 2 mm, 1.4301 / 1.4571

Chain tensioning: Spring spindle, gravity tensioning

Type of drive: Shaft mounted gear box (parallel shaft or helical bevel)

Housing: Can be manufactured from: ST 37-2 / 1.4301 (304 S) / 1.4571 (320 S 31) / 1.4541 (321 S 31) / PE - Basalt or ceramic lining

The conveying capacities are theoretical, calculated using a 100 % fill rate and 50 Hz.

Installations throughout industry: Aluminium works - activated carbon works- building material works

bio fuel factories - coal briquette works - chemical industry - fertilizer manufactrers - meat industry

plaster manufacturers - cereasis power stations - lime works - sewage plants - power stations

plastic industries - copper industry - food industry - mineral mill works - incinerating plants - oil mills

paper works - soot producers (gas, oil, carbon black) - steel work - tobacco product manufacturers

wall paper industry - animal cadaver processing - soap industry - sugar refineries - etc.

Please click for:

➔ Drawing and Dimensions