Microflex

The universal sensor

The specialist for difficult applications.

The specialist for difficult applications.

The sensors in this range are specialists for difficult applications.

They give you high-precision measurements even under extreme conditions.

The Microflex sensors are largely indifferent to the most diverse forms of interference and consistently deliver exact results where other methods fail.

A technique that really takes the lead

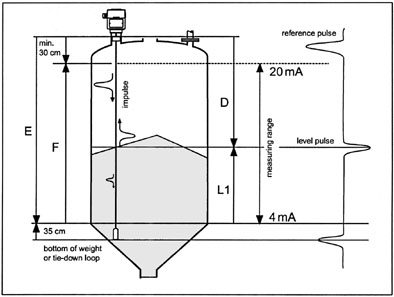

A special technique makes it all possible: a short microwave impulse is guided along a cable and reflected by the process medium. A sensor integrated into the electronics determines the level of material in the vessel by analysing the impulse's transit time and shows the exact numerical value clearly on a display.

Areas of application

The Microflex is a compact level transmitter for bulk solid applications. It has a galvanically isolated current output, optionally with HART communication signal. The probe is mounted in the top of the silo and measures the time that a high frequency impulse requires to cover the distance from the process connection to the product surface and back - the time of flight.

Microflex measures independent of the physical properties of the bulk solid, e.g. moisture content, grain

size, pressure and temperature. It is suitable for all bulk solids with grain size up to 20 mm and a dielectric constant of 1.8 or greater, e.g. sand, cement, limestone, agricultural products, flour, animal feed, fly-ash

or coal.

Advantages

Guiding through the cable amplifies the microwave impulse. It's this feature that provides Microflex sensors with enormous advantages for difficult measuring tasks such as:

· Indifference to dust and vapour:

Even extreme process conditions such as high dust content or a high degree of vapour formation have no

influence on measuring precision.

· Unaffected by material fluctuations:

Certain characteristics, such as density, granulation or moisture content, are subject to considerable

degrees of fluctuation. These have just as little effect on the measurement result as varying positional

angels of repose do.

· A wide range of measurement and pressure:

With a measurement range of 0 - 20 meters, Microflex sensors are also suitable for high, narrow vessels.

The wide pressure range up to 16 bar and the indifference towards vessel design open in a whole new

spectrum of possible applications.

· For unsettled surfaces:

Microflex sensors are ideal for agitated processes where surges in the bulk materials may occur.

Easy connection

A single twin-wire lead is sufficient to supply the Microflex sensors with power and to transmit the output signal. The measurement can be output either as a digital signal or in form of an analogue current

( 4 - 20 mA). In the case of sensors with a digital output signal (PROFIBUS PA, VBUS or HART-Multidrop), you can connect up to 32 sensors to your field bus via a single two-wire lead, depending on the protocol.