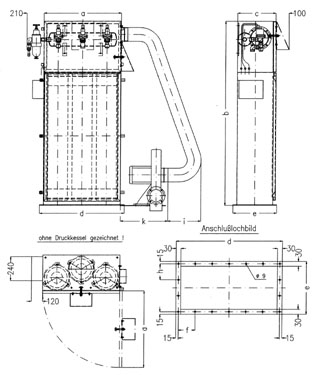

Loader Filter Type BELFI

For economical dedusting of Jet-Loaders when loading silo vehicles and containers

Areas of application

The loader filter TYPE BELFI serves for the direct dedusting and dust feed-back when loading silo vehicles and containers with a jet-loader.

Its compact design permits its application for the dedusting of air conveyor channels, enclosed conveyor belts, silos or bunkers which are gravity-filled without pressure.

High quality, coated material or the stainless steel model allow the use of the loader filters in almost all industrial sectors. Special attention was given to the problem-free dust feed-back of the filter dust into the silo vehicle.

Operation

Dust separation is accomplished via the filter elements which are cleaned-off singly, in sequence with short blasts of compressed air. The cleaning-off blast comes from a pressure reservoir and special valves.

A pressure reducer with fines filter is connected to the pressure reservoir - installed in the clean gas compartment - so that the cleaning-off pressure from 3 - 4 bar can be regulated.

The dust exhaust is carried out via a variably attachable ventilator. The loader filter is equipped with a vacuum shutter installed in the clean gas compartment. This shutter assures that no vacuum of more than

5 mbar develops in the system, thus making any damage to the elbows impossible. The optional filter control includes an easily adaptable filter cartridge cleaning feature. For the first time this permits cleaning-off the filter cartridges in short intermission periods after completion of loading. The performance checking device has been placed under the transparent control unit cover through which the cleaning process is displayed via LEDs. Expansion modules include a filter function control for the supervision of the filter cleaning operation. The device ensures that an electrical or pneumatic break-down, such as, for example, a cable break or the absence of air pressure, is indicated on a display. Failure of the filter and the resulting dust development will, of course, also be indicated.

For use with filters subject to extreme work-loads and for the optimum protection of the filter plant, a thorough check for any possible dust blow-out in the exhaust air pipeline is offered. With slightly damaged filter certridges an increased dust blow-out occurs shortly after a cleaning-off blast. This condition is detected and indicated as a disturbance.

An extension through an additional valve control unit is possible with the loader control unit so that not optimally constructed transition pieces can be cleaned-off pneumatically together with - and in the same cycle as - the filter cartridges.

Material/design

Filter-housing of sheet metal, plastic coated

Hammertone silver grey or stainless steel.

Ventilator and magnetic valve coil voltages are variable and both items can also be supplied in an explosion-proof version.

Advantages

· Explosion-proof version available on request

· Economical dedusting of loaders

· Compact design

· Large door openings for cleaning and maintenance

· Variable magnetic valve voltage

· Filter dusts are fed back into the bulk material - no disposable waste results

*Optional filter Control FST 1

*Optional filter Control FST 1