Big-Bag-Discharge System

The reliable solution for any discharging problems, feat. the following:

- secure handling of bulk bags

- secure handling of bulk bags

- dust-free discharge

- simple and easy to operate construction

- solid construction, low maintenance

- discharge aiding bag bottom

- applicable for all bag types and sizes

Due to the modular construction, single solutions can be combined to get a complete discharge system adapted to each need.

The dischargers can be connected to all common conveying systems, and can be used for the direct filling of silos and tanks.

For screw conveyors and flexible lifts, we offer feeding adapters with a guaranteed product inflow.

For the handling of bags, we manufacture traverses for the transport with forklift or crane.

Different tightening systems keep the Big Bag in shape so that the complete discharging is guaranteed.

Four different types are available:

1. Simple discharge for non dusty granulates with hopper. Low priced version.

2. Discharger with connection for the big bag outlet.

3. Standard discharger for highest capacity and secure discharge ofeven poorly flowing materials.

4. Discharger with docking system for highest demands on cleanness.

The secure bag support on the hopper resp. the support frame is the most important feature of all Big Bag discharge stations. Due to this, it is secured that the operator does not open the outlet fastening under a floating load.

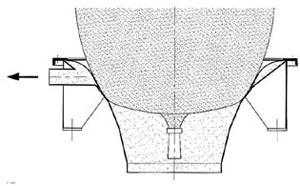

The hopper construction, used for all dischargers, allows to form the bag bottom to an easily flowing funnel with steep walls. This reduces the building of bridges in the bag’s discharge range.

In connection with the proved and tested vibration discharging aid, this effect will be improved enourmously. The low-frequency vibration drivewith high amplitude avoids product compression.

An effective vibration insulation decouples the vibrations.

The main part of the Standard discharger is the hopper which combines the following functions:

- Bag support for the operator’s protection

- Forming of bag bottom and discharge range for better discharge.

- Dust sealing by membranes.

- Extension of the Big Bag’s outlet so that a mechanical bag tightening is not necessary.

- The material buffer in the hopper allows a continuous discharge duringchange of bags.

Operation:

The fully filled Big Bag is put on the hopper by a crane, a forklift oran integrated lifting gear.

The bottom of the Big Bag is closed about the sealing membranes in a dust-proof way.

It partly immerses in the membrane’s opening and is put against the inclined hopper walls.

Between sealing membranes and hopper is an air flow which is extracted by suction via lateral connection pieces. The air extruded will be suckedoff so that any dust cannot be emerged. The aspiration dedusts themembrane opening during change of bags.

The lower part of the hopper includes the operating door where the outlet connection is mounted when using multi-way bags. The outlet connection end is lower than the door so that the product cannot be emerged during bag opening. The operating door is aspirated effectively via the lateral connection pipes.

The outlet hose of the Big Bag can be elongated into the hopper during discharge.

A re-tigthening of the Big Bag is not necessary.

The hopper is specially designed to discharge even poorly flowing and bridge building bulk goods.

The hopper is specially designed to discharge even poorly flowing and bridge building bulk goods.

An effective discharging aid is the vibrating cone with electro vibrator and compressed air vibrator, adjusted for loosening. The discharge system is maintenance free, without bearings, and without joints and guidings. For that, it is suitable for continuous operation in even harsh environments.

Cleaning during change of material, also due to hygienic standards, is very simple as there are no dead spots.

This underlines the suitability as all-purpose equipment for all fields, whether chemical industry and food industry, recycling, or building materials.