Bucket elevators

(chain bucket elevators + belt bucket elevators)

Chain Bucket Elevators

Chain bucket elevators are very robust conveyors for arduous operation, also under high temperature conditions and handling extremely abrasive or lumpy products.

We only use high-quality chain systems of renowned manufacturers.

As a result a maximum of operational safety and efficiency is given.

Chain bucket elevators are designed and manufactured individually for each project.

Design and engineering take into consideration the latest scientific findings.

Chain types:

- round steel chain

- single chain

- double chain

Chain wheels:

- non-toothed sprocket wheels with highly wear resistant segments

- toothed and specially heat treated

- individually designed types

Chain tension:

- parallel tension with weights

- ballast tension system

- spindle tension with spring system

Bucket attachment:

- chain shackle

- plug-in attachment

- continuous chain loop with clamp system

Options for installation of the return drum bearings at the boot:

- internal installation with grease lubrication or in the oil bath

- rotation monitor

- backstop

- driving power monitoring (option)

- safety switch at cleaning and maintenance doors (option)

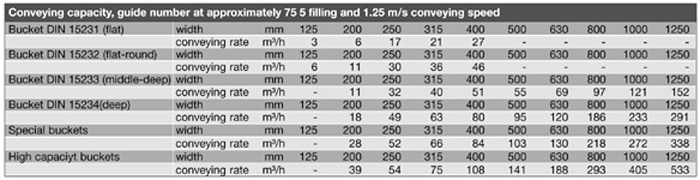

Conveying capacity: 3 - 450 m³/h

Conveying materials: extremly abrasive, lumpy as well as hot bulk materials, free flowing,

scoopable

Conveying speed: 0,8 - 1,6 m/s

Temperatures: -100 - +300°C in special cases higher temperatures too

Safety systems:

- filing level indicator - rotation monitor - backstop

- driving power monitoring (option)

- safety switch at cleaning and maintenance doors (option)

Belt Bucket Elevators

Belt bucket elevators are quiet in operation and have proved themselves suitable for corrosive media

and foodstuffs. Different kinds of belts of special elastomers with textile or steel wire reinforcing are

used according to the application and the conveying height.

The belt bucket elevators are designed and manufactured to individual requirements.

Additionally we consider the latest developments and our many years of experience.

Belt variations:

- belts with extremely high tensile strength and low stretch for great conveying hights

- food quality

- temperature resistant up to 180° C

- corrosion resistant belts

- antistatic belts

- oil and grease resistant versions

Divert and drive drum:

- drive drum with shaped elastomer lagging

- drum without lagging

- cage type drum with material deflection cone

Belt tension:

- automatic parallel tension device - spindle tension

Options for installation of the return drum bearings at the boot:

- internal installation with grease lubrication or in the oil bath

- external installation in pillow block bearings with slide seal

Bucket attachment:

- bucket screw mounting for light bulk materials

- screw connection with semicircular backing plate for heavy bulk materials

- vulcanised fittings and countersunk head screws for application in high capacity bucket elevators

Conveying capacity: 3 - 800 m³/h

Conveying materials: powder and granular as well as lumpy bulk materials, free flowing, scoopable

Conveying speed: 0,8 - 4,0 m/s

Temperature: -30 - +180°C

Safety systems:

- filling level indicator

- rotation monitor

- backstop

- belt tracking controller

- driving power monitoring (option)

- safety switch on cleaning and maintenance doors (option)